-

自动表面光学疵病检测基本原理及产品介绍

2021-03-01

-

激光功率测量仪器基本原理及产品介绍

2021-02-20

-

非接触式测厚仪基本原理及产品介绍

2021-02-02

-

消色差波片的基本原理及产品介绍

2020-12-30

-

太赫兹技术与太赫兹产品介绍

2020-12-17

-

声光Q开关的基本原理及产品介绍

2020-12-09

-

偏振器件的基本原理及产品介绍

2020-12-01

-

线扫系统及线扫镜头介绍

2020-10-29

-

激光反射镜的选型和常规指标介绍

2020-09-22

-

远心镜头的选型和常规指标介绍

2020-08-26

-

光栅的常规指标介绍和选型指南

2020-08-10

-

棱镜的选型和常规指标介绍

2020-08-05

-

工业镜头常规指标介绍和选型指南

2020-06-15

-

滤光片的选型和常规指标介绍

2020-06-05

-

分光元件的选型和常规指标介绍

2020-05-15

-

波片的选型和常规指标介绍

2020-04-30

-

光学元件的表面清洁方法

2019-11-29

-

Industrial Lens Soft Service--Resolution Information

2019-11-01

-

Aspheric lens processing

2019-10-30

-

Analysis of Key Points of Coating on Complex Spectroscopy Spectroscope

2019-09-29

-

High-resolution short-wave infrared lens with large target surface

2019-02-13

-

Long-distance lighting line scan light source

2019-01-10

|

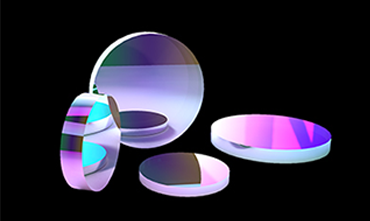

Analysis of Key Points of Coating on Complex Spectroscopy Spectroscope

|

|||

| With the development of optical technology and the improvement of market demand, the coating technology of complex spectrum lenses has begun to be widely used in many scenarios. Let's take a look at the analysis of the main points of complex spectrum spectroscope coating. |

|||

|

Complex spectrum lenses mainly include filters, beam splitters and beam combiners, etc. The efficiency problems mainly come from the following two aspects: 1. Depolarization treatment under 45° incident conditions For any optical film (single-layer film or multi-layer film), the effective refractive index of the material determines its spectral characteristics:

2. The steepness of the transition from the reflective zone to the transmissive zone

The thermal deformation of strong light optical components mainly comes from the absorption of the components, and the absorption source mainly comes from the following three aspects: 1. The lens element substrate absorbs. To circumvent this, low-absorption Corning quartz or Heraeus quartz can be used as the substrate. The above are some of the main points of the complex spectrum spectroscope coating. If you want to know more, please contact us. United Optical Technology is a spot supplier of standard optical components in China, committed to providing users with various optical components, as well as providing customized services for optical products. Any need for your optical components, we will serve you wholeheartedly and look forward to your contact.

|

|||